In today's highly competitive production industry, staying ahead of the competition requires efficient and effective tools that are readily available in the market. One of the devices that have revolutionized the industry of plastic injection moulding has been Hot Runner PET Preform Mould. This tool is used extensively to make preforms that are used as a basis for bottles, plastic containers, and other things. The technology offers manufacturers a variety of advantages. In this blog, we'll explore how the hot PET moulds from Hot Runner will boost production, the quality of their products, and the efficiency of all operations.

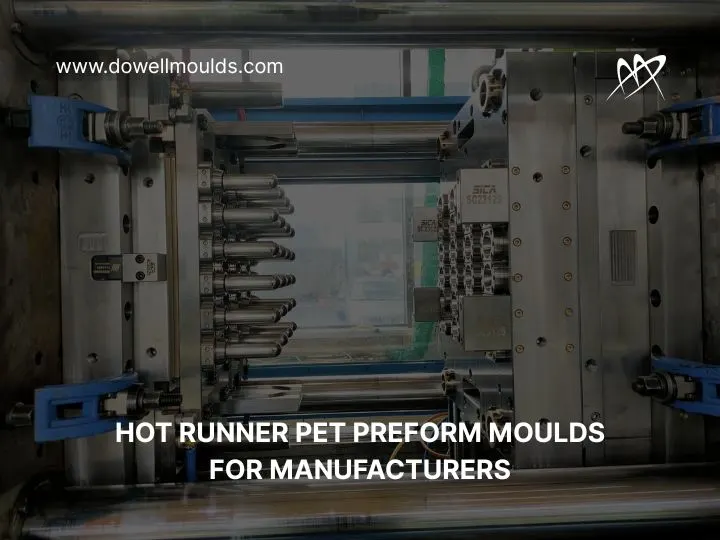

What Are Hot Runner PET Preform Moulds?

Before examining the benefits and looking at the benefits before reviewing the benefits, you must understand the basic concepts of Hot Runner PET Preform Moulds, how they work, and the way they work. Unlike cold-runner models, where the material is a solid inside the runner before being introduced into the cavity, runners keep the plastic at a melting temperature that allows for effective circulation and faster processes.

Preforms made of PET have been created to create the preform into a small size, resembling a test tube's shape. It is employed to produce bottles, containers, and other items similar to these. Preforms can be bent, blown or further moulded into the desired shape. Hot Runner PET performs moulds with a range of advantages over traditional systems that must be considered by makers who demand top quality and efficiency. Here are the key benefits of using hot PET moulds in your manufacturing process.

1. Reduced Material Waste

One of the biggest advantages of hot Runner PET perform moulds is eliminating discarded ones. In cold-runner processes, the plastic not made into the mould will be removed or reused. However, melting plastic remains within the runner with hot runners until it is in the mould. It reduces the amount of plastic left after the process of injection.

The result is that businesses can get more use of the raw material that they utilize, resulting in less waste and less expense for the material. When the time comes, it can be an important saving for companies where the cost of raw materials is high.

2. Improved Cycle Times and Production Efficiency

These Hot Runner PET Preform Molds are capable of quicker injection procedures than traditional cold runner techniques. The hot-runner procedure ensures the plastic is kept at a constant temperature during the entire injection process. It also decreases the time needed for the material to harden and chill. The result is that producers can produce more preforms in a shorter time and increase the overall efficiency.

In addition, the speedier cycle speeds up production, allowing manufacturers to meet a greater need with the time they need and fewer interruptions. For industries where production speed is crucial, efficiency is a major benefit.

3. Better Product Quality

Preforms made of hot PET moulds ensure more reliable and top-quality products. The preforms made are less susceptible to surface imperfections, such as walls with thicker layers, uneven sink lines, and poor-quality finish at the top.

The ability of PET to maintain the temperature can reduce the risk of crystallization or loss of material, which will affect the product's strength and clarity. The result is that producers and manufacturers can make PERforms with better dimensions, a consistent thickness, and

4. Energy Efficiency

The hot runner helps keep the plastic material at an even temperature, which can save energy. When using a cold-runner system, plastic must be warmed up every time it moves through runners, creating a lot of energy consumption. The hot runner requires power to maintain its temperature. Runners, and even the runner itself, are efficient in energy use.

With time, the reduction in energy use could translate into huge savings in expenses, especially in large manufacturing plants where equipment runs for long periods.

5. Enhanced Flexibility and Customization

Hot Runner PET Moulds maintains good flexibility with increased adaptability for high-quality production. These moulds are perfect for manufacturing units and storage stations developing multiple items or changing their manufacturing process. Hot-runner technology allows

flexibility in the properties of the preforms, such as wall thickness and distribution of the materials.

6. Reduced Labor Costs

Hot Runner PET preform moulds might be more expensive upfront than traditional cold-runners but can result in huge savings over time. With fewer cycles, lower usage, and less demand to use manual interventions, manufacturers can reduce the cost of labour.

Particularly, the less necessity for workers to deal with their waste or modify the production process could allow employees to concentrate on other jobs. Furthermore, the greater efficiency of hot-runners implies that fewer machines are needed to meet production goals and lessen the need for large teams of employees.

7. Minimized Maintenance and Downtime

Hot Runner PET Molds are great for their durable quality. Older cold runners require frequent maintenance to address problems like blockages or accumulation of chemicals inside the runners.

By avoiding repair and maintenance that is not needed, manufacturers can make sure the production line runs efficiently and improves overall performance.

8. Environmental Benefits

Hot Runner PET Moulds reduces the environmental impact by disposing of unnecessary wastage and maintaining a sustainable environment. They require less energy and less product to be used in the production process. The equipment will assist businesses to meet sustainability goals and reduce the carbon footprint they produce during their business. This becomes increasingly vital since environmental concerns drive technological advancements in production.

If they choose Hot Runner PET Moulds for businesses, they can boost their profit margins and contribute to creating a sustainable future.

Conclusion

The Hot Runner PET Moulds provides a group of advantages for manufacturers, including decreasing the waste of products and improving the quality of their products, increasing the effectiveness of energy use, and increasing the setuped for production processes. Businesses can boost their effectiveness, cut costs, and meet their clients' growing demands with high-quality and environmentally friendly products.

Hot Runner PET Molds are vital for companies that want to stay on top of the technological advances in today's industrial world.

In embracing this technological advancement, producers can rest assured that their methods remain sustainable and productive and will provide top-quality products for sale.