One of the most efficient methods to meet the demands can be Rhot Runner Cap Moulds. Manufacturers and producers can improve productivity, reduce their waste material, and increase the efficiency of caps made from plastic. In this blog, we will look into the purpose of moulds for caps produced by hot runners to produce large quantities, along with their benefits and why they're the most sought-after choice for producers across the globe.

Understanding Hot Runner Cap Moulds

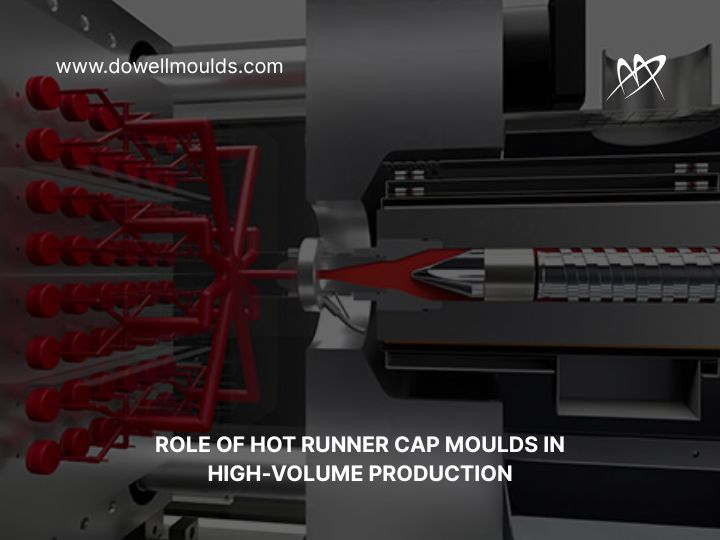

The cap mould for hot runners is an extremely well-designed and crafted injection mould that features the option of heating the runner so that the plastic remains at the same temperature throughout the injection process. Contrary to traditional cold-runner moulds that see the plastic solidify within the runner before injection into the mould cavity, hot runners provide a constant flow that melts plastic. They can also eliminate waste materials and speed up the cycle time.

How Does a Hot Runner Cap Mould Work?

The system is comprised of:

- Manifold Manifold disperses the melting material evenly across several chambers.

- Nuzzles are used to inject the chemical into the mould cavity.

- Temperature Control System: Ensures uniform heating for consistent cap quality.

Key Advantages of Hot Runner Cap Moulds in High-Volume Production

1. Faster Cycle Times and Increased Productivity

One of the primary benefits that Hot Runner Cap Molds have is the ability to enhance the injection rate. It speeds up the process of injecting.

- Reduces the time to cool: The manufacturing process can be completed much more quickly, and no plastic is added to the runners to remove and cool.

- Extra Output Per Minute: more than one minute of processing increases output levels. It allows companies to satisfy the demands of large volumes efficiently.

In fields that need millions of caps per day, its efficiency proves greater profits and faster fulfilment of orders.

2. Reduced Material Waste and Cost Savings

Cold runners, also known as typical, produce a large quantity of waste made up of polymers that have been solidified. It is essential to recycle the garbage (adding cost to process it) or to dispose of it. The result is an increase in the price of materials.

With Hot Runner Cap Moulds:

-

The running shoes consist of solid material and durable plastic. This signifies that every gram of plastic used is effective.

3. Improved Cap Quality and Consistency

Cap Moulds offer top high-quality products due to:

- Uniform material flow This method ensures that each hole stops the growth of bubbles and moving lines.

- Increased accuracy of dimensions Caps are equipped with exact dimensions and weights that ensure the same quality across various sizes.

- Enhanced Surface Finish The smooth top quality and high-end finish removes the requirement for processing it following.

4. Energy Efficiency and Sustainability

- Lower Energie Consumption This results in decreased energy consumption because it doesn't require heating or perforation to recycle.

- Reducing the amount of waste made of plastic leads to a smaller environmental footprint.

5. Scalability for Large-Scale Production

This is vital for companies that produce millions of caps per day.

- 24 hours of high-speed production: Hot-runners enable rapid and efficient production without interruptions.

- Multi-Cavity designs: Based on the need, mould makers can utilize the 32, 48, 72, and 96 cavity moulds to enhance effectiveness.

Hot Cap Moulds for Runners has unbeatable manufacturing capabilities for companies looking to expand their business.

6. Reduced Maintenance and Downtime

While Hot Runner Cap Molds need more initial capital investment, They also have an easier maintenance expense.

- Using fewer mechanical components As opposed to cold runners, no other elements must be changed regularly.

- Efficacious cleaning requirement: The cleaning process is made shorter due to the absence of any formed plastic inside the runners.

- The mould that lasts longer: The lack of solidified runners results in less wear and tear and prolongs its lifespan.

Businesses can guarantee continuous, effective quality and efficient production by reducing their machine's time to downtime.

Hot Runner Cap Moulds are the best choice for production on a large scale, as they provide greater efficacy, reduced losses, and greater effectiveness.

Hot Runner Mould vs. Cold Runner Mould: A Side-by-Side Comparison

|

Feature |

Hot Runner Mould |

Cold Runner Mould |

|

Initial Cost |

High |

Low |

|

Material Waste |

Minimal |

High |

|

Cycle Time |

Faster |

Slower |

|

Maintenance Complexity |

High |

Low |

|

Energy Efficiency |

High |

Low |

|

Automation Readiness |

High |

Moderate |

Conclusion: Why Hot Runner Cap Moulds Are Essential for High-Volume Manufacturing

Cap Molds Cap Molds Runner Cap Moulds have revolutionized making caps out of plastic since they permit shorter production times, reduced prices, and better product quality. Companies looking to boost production, decrease waste, and satisfy their growing requirements from their customers invest in Hot Runner Cap Mould technology, which is an effective and long-term purchase.

Although the initial cost may be more expensive, the long-term benefits (such as more production capacity, lower energy cost and less maintenance) will outweigh the initial costs of investing.

Producers can be effective, sustainably, and productive in an ever-changing marketplace. Cap Moulds Runners.