Selecting the best moulding method is vital for those who want to increase the efficiency of production as well as reduce expenses, and ensure top-quality production. Two popular injection moulding methods include Hot Runner Moulds and Cold Run Moulds. Each offers its distinct strengths, weaknesses and the best applications. Knowing their strengths and weaknesses will help companies make an informed choice aligned with their manufacturing needs and business objectives.

This post will discuss the difference between hot and cold runner moulds. In this article, we'll explore the working principle behind them, their advantages and disadvantages, and which is the most suitable to meet the various manufacturing needs.

What is a Hot Runner Mould?

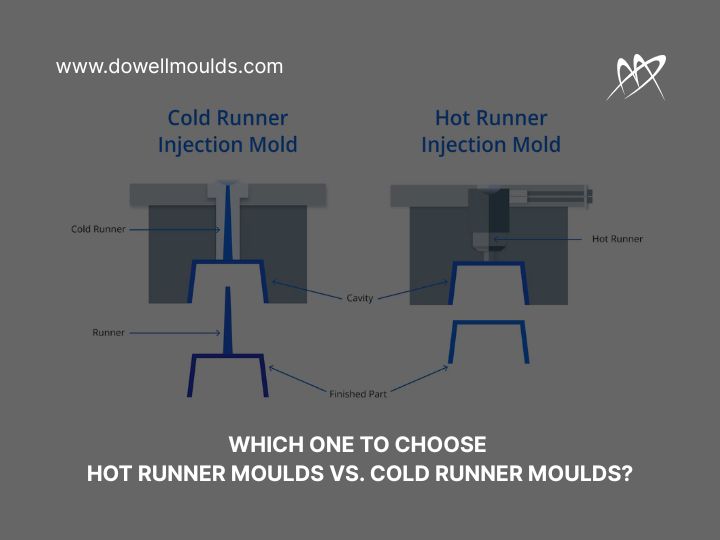

The hot Runner Mould is an injection moulding technique that utilizes heated parts to keep the plastic in a melting state inside runners. Hot Runner Mould does away with the need to solidify runners and sprues, ensuring that the melting material can flow directly into moulding cavities.

How Does a Hot Runner Mould Work?

Hot-Runner Molds comprise of two major components:

- Manifold distributes the melting plastic equally to every nozzle.

- Nozzles Then, pour the plastic that has been melted into mould cavities.

The system's heating keeps a constant temperature and prevents the material from solidifying before it reaches the moulding cavities.

Advantages of Hot Runner Moulds

Material waste reduction: Since the plastic is still molten, it has no sprues or runners to throw away, thereby reducing the amount of material wasted.

Accelerated Time to Cycle: Hot Runner Moulds enable an uninterrupted flow of molten plastic that reduces the time needed for cooling and heating, which results in faster production times.

Enhances quality of product: Better control of the flow of materials ensures uniform filling, minimizing defects such as line lines, sink marks, and irregular wall thickness.

Energy Efficiency: Reduced plastic regrinding and reheating processes result in less energy usage than cold runner moulds.

Automatization-Friendly: Hot Runner systems can integrate into automated production lines, which makes the human.

Disadvantages of Hot Runner Moulds

It is expensive to start. It requires more heating elements, which makes the system more costly to build and set up.

Complex Maintenance requires experienced technicians to diagnose and repair heaters and temperature controls.

More time to set up: More time is required to install and fine-tune the heating system before production begins.

What is a Cold Runner Mould?

The cold runner moulding process is a traditional injection moulding process where plastic is pushed through runners that are not heated before entering mould cavities. When the material has filled the mould cavity and becomes solid, it is left in the runner and removed, as well as the final piece.

How Does a Cold Runner Mould Work?

Cold Runner Moulds feature three or two-plate designs :

- Two-plate moulds: Eliminate the component and join the runner in a single piece, which requires manual or automated removal.

- Moulds made of three plates Automatically segregate the runner from the finalized part at the time of Ejection.

Advantages of Cold Runner Moulds

- Lower initial cost: ColdRunner Moulds have an easy and customer-friendly construction and don't require extra heating elements. This makes the moulds more cost-effective.

- Simple Maintenance The absence of heating elements means less technical Maintenance and simpler troubleshooting.

- Flexible Materials Selection: Suitable for an array of thermoplastics, including those affected by overheating.

- A shorter set-up time: Faster configuring and installing over Hot Runner Molds.

Disadvantages of Cold Runner Moulds

- High Material Waste Each cycle generates excess plastic shaped into runners and sprues. This leads to a rise in the cost of materials, especially if scrap material is not recycled.

- Slower cycle Time: The extra steps of cooling Ejection and separation of the runners prolong the production cycle.

Hot Runner Mould vs. Cold Runner Mould: A Side-by-Side Comparison

|

Feature |

Hot Runner Mould |

Cold Runner Mould |

|

Initial Cost |

High |

Low |

|

Material Waste |

Minimal |

High |

|

Cycle Time |

Faster |

Slower |

|

Maintenance Complexity |

High |

Low |

|

Energy Efficiency |

High |

Low |

|

Automation Readiness |

High |

Moderate |

Choose Hot Runner Moulds If:

It is necessary to have large-scale manufacturing using minimal production waste.

The priority is speedier process times to meet the demands for high volumes.

You're looking for quality products that have uniform fillings and no flaws.

You're ready to invest in modern automated systems and cost savings long-term cost savings.

Choose Cold Runner Moulds If:

If you have the benefit of a small amount of money and would like a smaller initial investment.

There are high-temperature materials that can degrade when used in the hot runners device.

The production runs you have a small or medium-sized and where the material waste can be managed.

You're seeking simple Maintenance that uses fewer technical complications.

Conclusion

Each Hot Runner Mould, as well as Cold Runner Mould, has its advantages and weaknesses. Although Hot Runner Moulds provide greater efficiency, less production waste and better product quality, they need an initial investment and more expertise in Maintenance. However, Cold Runner Moulds initially offered lower costs and more flexible material. However, they also have greater product waste and slower production times.

Hot Runner Moulds are preferred in large-scale, high-efficiency production, even though they are more expensive. However, Cold Runner Moulds could be more appropriate for smaller productions or various material requirements.

The final decision is based on your production goals, budget, and long-term plan. If you take the time to evaluate the needs of your manufacturing company, then you can choose the method that will best meet your business goals.